We’re getting feedback in real time from the field versus before it might be months before we could even take a look at different sites.

Grocery BOH Operations

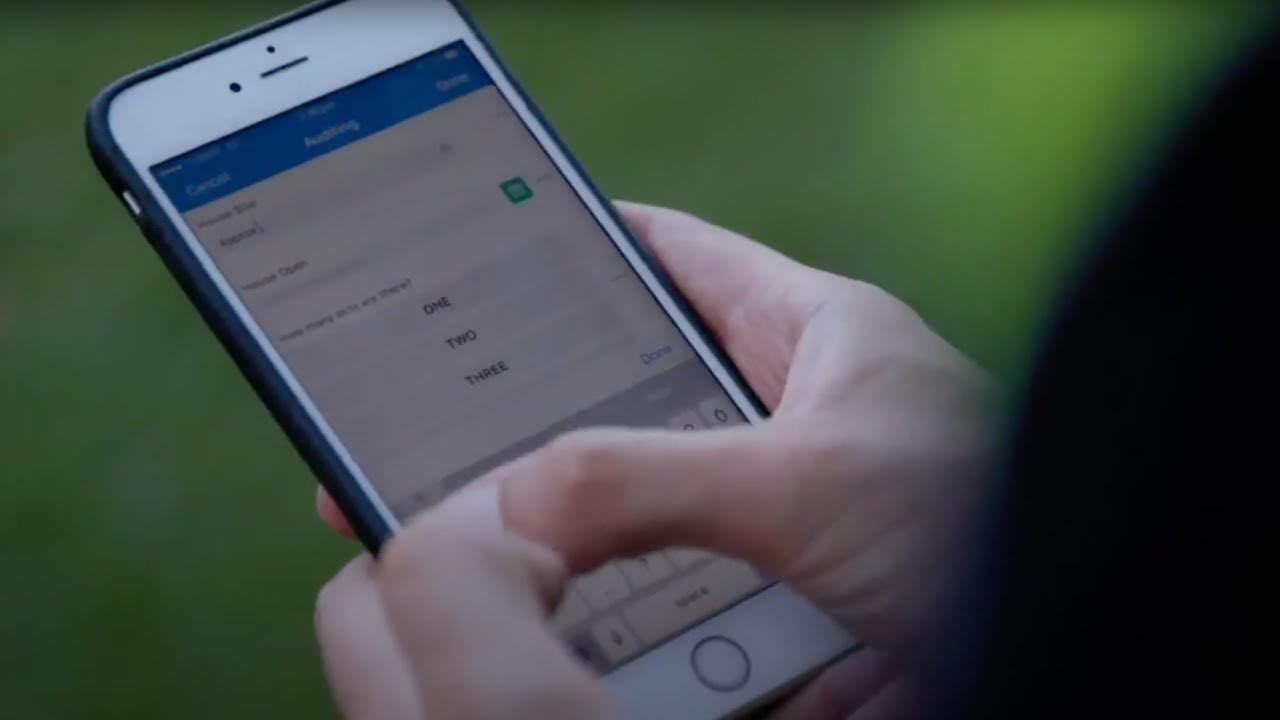

Workplace operations platform

Boost efficiency, ensure safety, and maintain quality across every facility—from manufacturing to warehousing.

SafetyCulture’s workplace operations platform gives you real-time visibility, digitized workflows, and easy collaboration to minimize downtime and maximize ROI.

saved across the organization — Sodexo

saved from loss prevention — Lowe's

point gain in guest satisfaction — Waldorf Astoria

Empower your grocery teams with a mobile-first operations platform built for the aisles and the back office. Keep your food and people safe, raise standards, and improve every day—all in one easy-to-use platform.

We’re getting feedback in real time from the field versus before it might be months before we could even take a look at different sites.

Getting SafetyCulture out to 760+ shops, with so many employees was surprisingly easy. It’s not often you get that in a roll out of this magnitude. We rolled it out in a matter of weeks.

One of our customers is even using SafetyCulture platform, so we can liaise with them in real-time. That means we’re confident every element, from pre-production checks and freight to measurements and auditing, is as streamlined as possible.

A manufacturing company gained visibility into its operations with SafetyCulture’s dashboards, which provided real-time updates from facilities. For example, when one facility implemented a process that reduced defective products by 30%, corporate scaled the practice system-wide, saving significant costs and improving efficiency.

A warehouse reports hazards through SafetyCulture, enabling instant corrective actions. In one instance, a machine hazard was flagged and resolved within hours, avoiding a costly injury.

By digitizing maintenance schedules and task assignments, one company reduced downtime by 20% across its manufacturing facilities. Teams resolved issues faster and coordinated more effectively.

A manufacturing company streamlined training with mobile-friendly tools, reducing onboarding time by 40%. New hires were better prepared, and employee retention improved.