6S Lean: 5S + Safety

6S (otherwise known as 5S + Safety) is a system that aims to promote and sustain a high level of productivity and safety throughout a workspace. While adhering to the 5S principle of Sort, Set in order, Shine, Standardize, and Sustain, the 6S method adds the concept of Safety. 6 S lean not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety.

The 6 Components and Their Importance

What are the components of the 6s lean methodology and what is their importance in the overall system? Let us walk through each of the 6 S.

- Sort (Seiri)

Sorting, the first step in the 6s methodology, aims to reduce clutter and make it easier for essential work items to be easily located for improved efficiency. “Red tagging” is often done to mark unnecessary items for immediate disposal, while “yellow tagging” can be applied for those items that can be temporarily kept off-site for future use. - Set in order (Seiton)

In this stage of the 6 S system, items, equipment, and work materials tagged as essential in the first stage should be placed in an organized manner in the most logical locations. The objective of ‘Set in Order’ (or ‘Straighten’) is to establish a systematic way of storing and retrieving items, thus helping maximize accessibility and space. - Shine (Seiso)

After non-essential items have been removed and essential items have been organized, the next step is cleansing. The third stage of the 6s lean system, also known as ‘Shine’, includes activities, such as cleaning the workplace, maintaining its pleasant appearance, and using preventive steps to keep workspaces tidy and clean. The objective is to create an environment that prevents injuries and products from being stained due to uncleanliness. - Standardize (Seiketsu)

‘Standardize’ is the fourth 6s method stage that aims to establish a new workplace norm by identifying best practices and creating consistent procedures for the first three stages. It aims to help people have the same work routines in their processes and develop more efficient habits. This can be done by providing visual reminders, setting expectations of workers’ responsibility, and conducting routine inspections and regular site checks. - Sustain (Shitsuke)

This is the most challenging step of the 6S method as the goal is to ensure that standardized procedures are applied continually over a long period of time until it becomes second nature in day-to-day work. - Safety

Lastly, 6S lean features Safety as the final step added to the standard 5S methodology many have been used to. This essential step of 6 S focuses on identifying hazards and setting preventive controls to keep workers safe during work operations and ensure that the work environment meets required safety standards.

Why Include Safety?

We know that Safety is the topmost priority in every workplace. Having a safe and clean working environment helps:

- Create a positive impact on productivity and quality;

- encourage a stress-free and healthy atmosphere where workers can feel safe and secure; and

- make it easy to recognize potential hazards and install safety controls.

Some believe that Safety is already integral to the classic 5S methodology; why then should it be incorporated as a separate step?

One reason lean improvement professionals say is that adding Safety helps provide further focus on safety issues, especially for industries that involve high-risk jobs, such as construction and food manufacturing. The extra attention given can help ensure that no hazardous items or conditions are overlooked after going through the five stages of 6s lean.

Further, having Safety as part of the 6S system can help an organization to:

- Be more prudent on expending energy, materials, and other resources;

- Avoid productivity losses from injuries and occupational health hazards by providing clean and accident-free work areas; and

- Meet or exceed environmental performance and waste reduction goals

Improve your EHS Management

Cultivate a safe working environment and streamline compliance with our EHS solutions.

Explore now6S in Manufacturing

6S in manufacturing is an approach to production that integrates the 5S principles (Sort, Set in order, Shine, Standardize, and Sustain) in manufacturing processes, with the additional factor of Safety. This method helps address critical manufacturing issues. For example, operators who practice 6S in manufacturing and implement 6S lean programs enhance the safety of their employees including the working environment and operational equipment to improve efficiency on the factory floor.

Safety in manufacturing plays an essential role in determining overall employee productivity. Conducting 6S audits and implementing 6S lean programs can help manufacturing industries to achieve the following:

- advanced waste management and cost reduction;

- reduced machine breakdowns;

- high-quality products; and

- effective employee onboarding and 6S training programs.

6S Lean Requirements

To fully implement 6s lean in your workplace, you’ll need the following:

- Thorough understanding of / experience with 5s

- A system for identifying and reporting hazards

- Safety awareness training relevant to your industry

- Commitment to have toolbox talks with your workers about 5s/6s

- Approval from upper management along with dedicated resources and support

Different Ways to Complete the Safety Step

The first step to safety is identifying existing hazards and those which are likely to be present in the workplace. All employees must be aware of the different types of workplace hazards and evaluate these hazards through risk assessments or a Job Safety Analysis (JSA). These prerequisite methods carry out standard safety procedures and necessary controls to reduce or eliminate these hazards.

Workers should also wear appropriate Personal Protective Equipment (PPE) as additional protection to hazards that are difficult to control or can not be eliminated. PPE includes hard hats, safety goggles, face masks, insulated gloves, slip-resistant boots, and a lot more. The use of PPE must be checked and other safety protocols must be disseminated to all workers through training and toolbox meetings.

Achieving 100% safety is never an easy task, but by incorporating safety to the original 5S method—and kaizen, you can help improve working conditions in your organization. Workers can not only focus on completing tasks for the day but can also habitually contribute to the overall workplace safety.

Training for 6S Lean Implementation

Maintaining a 6S lean lifestyle in the workplace goes beyond just having a set of how-to guidelines. It is also important to foster the right mindset among your workers so that safety becomes second nature to them.

One way to properly instill 6S lean concepts into your workplace is through regular training. Transforming your 6S lean principles and practices into interactive training modules accessible anytime and anywhere can help educate your workers on the safe and proper procedures that need to be observed in your workplace. In the process, you can also improve your organization’s implementing procedures in order to better suit your needs.

6S Lean Example

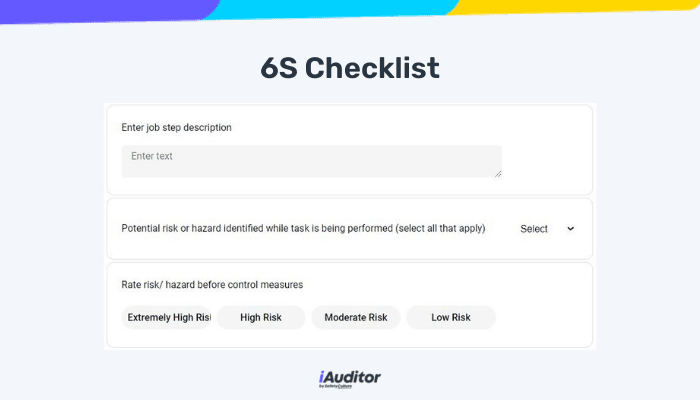

This example is a combination of the 5s Audit Checklist and the 6S Lean Safety Checklist provided by SafetyCulture for you to download and use for free:

Sort

– Check if only the required equipment, tools, furniture, and materials are present in the area.

– Remove obsolete or broken items not required for current projects from the area.

– Remove all tripping hazards such as electrical wires and equipment as well as cables from all working, standing, and walking areas.

Set in order

– Clearly identify equipment and furniture by numbering, naming, or color-coding.

– Place equipment and furniture in a properly identified location.

– Place tools in a designated storage area that is within reach of the user/operator.

Shine

– Maintain all Personal Protective Equipment (PPE) in a sanitary and reliable condition and properly store in an easily accessible and labeled location when not in use.

– Keep work areas (machines, workbenches, dies, and other equipment, including electrical boxes) clean and painted.

– Ensure that floors are free from dirt, debris, oil, parts, hardware, and empty boxes.

Standardize

– Implement preventative measures to ensure that the workplace meets 6s guidelines (e.g. systems that do not allow waste to accumulate, such as containers to collect debris from machines).

– Post the results of the previous 6s audit.

– Address the areas for improvement identified in the previous 6s audit.

Sustain

– Allocate time and resources to 6s activities (e.g., designated daily/weekly clean-up time, selecting a 6s team leader).

– Assign weekly 6s activities to all operators, team leaders, and supervisors.

– Give recognition to teams who actively participate in 6s activities.

Safety

– Identify potential hazards for each task being performed or for each part of the process.

– Conduct a risk assessment of each potential hazard and determine the risk rating.

– Establish hazard control measures (e.g., elimination, substitution, engineering controls, administrative controls, or PPE).

Create your own 6s Lean safety checklist

Build from scratch or explore free, ready-to-download, and customizable templates.

Browse 6s Lean checklistWhich System is Better for Your Organization?

When deciding whether to implement 6s or 5s for your team or company, it is best to assess which one will best meet your needs.

In workplace settings that are significantly more hazardous, it makes more sense to take the extra step and choose 6 S. This helps establish Safety as a crucial focal point of the organization and that there are specific Safety KPIs to be taken into account to measure improvement efforts.

Meanwhile, in workplace environments where there are very few significant safety risks, the 6th S may be considered unnecessary. In fact, having a 6th S in otherwise very safe environments could be seen as wasteful. When following 6S it is necessary to take the time to evaluate how different activities will impact the safety of the facility.

Whether you will implement 5S or 6S, organizations must remember that safety shall always be a priority. It is just a matter of choosing the right lean management strategy that will help meet your needs will while also ensuring that employees remain efficient with their work.

What is 6S Lean Software?

6s lean software is a digital tool that helps you carry out and document 6s implementation. Using 6s lean software such as SafetyCulture (formerly iAuditor), you can expect to get the following, as long as you are consistent with following your 6s system:

- Increased efficiency

- Standardized operations

- Higher productivity

Discover SafetyCulture features for 6s lean.

Implement and Audit 6S in Your Workplace Using SafetyCulture

Make your workplace clean and safe! Do it the 6S way! Get started by downloading these free 5S and 6S use cases on our SafetyCulture platform.

SafetyCulture gives you the flexibility to power any inspection you require. Whether you’re on-site, underground, or across the globe, conduct site inspections all in one platform designed for the unique needs of the manufacturing industry.

SafetyCulture Marketplace: Your One-Stop Work Gear & Equipment Shop

Improve safety in your workplace with SafetyCulture Marketplace as your one-stop shop for all work gear and equipment needs. Get on-demand access to top quality and specialized work gear from trusted equipment brands in the industry—all in one centralized location. Raise the bar of safety and efficiency by empowering employees to request what they need with just a few taps, anytime and anywhere!

FAQs About 6s Lean

Yes, the 6s or 6S methodology is a subset of the larger Lean approach to process improvement. As a quality management technique often utilized in workplace settings, 6s Lean helps identify and eliminate waste by focusing on organization and cleanliness to create a culture of continuous improvement.

The main difference between 5s and 6s lean is the addition of the concept of Safety when implementing the 5s methodology. This additional focus on safety allows organizations to proactively identify workplace hazards and operational risks that can otherwise negatively impact a business and its people, if not promptly recognized.

The origin of the 6S Lean methodology can be traced back to the principles of the Toyota Production System. TPS, which is also considered the foundation of Lean methodology, emphasizes the importance of eliminating waste and continuously improving processes from there.

The frequency of 6s Lean audits can vary based on each 6s element in order to identify and prioritize areas that need more improvement. For example, Shine activities can range from daily to weekly assessments, while actions relating to Sustain can be reviewed from weekly to monthly audits, or as frequently as needed. Basically, areas that require constant attention are audited more frequently compared to those that are already well-established.