What is Hansei?

Hansei is a Japanese word that means introspection or observation of one’s reflection. The word “Han” means to change or turn over, while “Sei” means to look back upon and examine oneself.

Hansei is a systematic approach used to recognize and contemplate committed mistakes in the project life cycle that helps understand misconception, inaccuracy, failure, and errors. It helps organizations comprehend appropriate action and how it can be improved to avoid recurrence of the issue. Hansei is commonly performed after projects are completed, during year-end reviews, or as part of employee self-assessments.

Importance of Hansei in Lean Manufacturing

Hansei plays an important role in lean manufacturing as it is one of the keys to Kaizen. It is a continuous practice to improve decision-making when an employee has self-realization of the mistakes that occurred in the past. It can help the organization in implementing continuous improvement and reap the following benefits:

- improve employee self-esteem;

- prevent reoccurrence of the incident;

- prepare the right approach to solve the problem; and

- discover what went wrong and what can be done to improve the process.

How to Perform Hansei?

Hansei helps employees to reflect on ideas and learn from either successes or failures to improve themselves in the future. It typically has three elements:

- recognition of a problem;

- acceptance on the responsibility of committed mistakes; and

- create action plans and commit to improvement needs.

Three Elements of Hansei | SafetyCulture

There is no formal format in performing Hansei as it can be done in a personal reflective manner or in a team setting. It can be a brief reflection of performances and ideation of what went wrong. Here are the basic steps to perform Hansei.

- Identify the problem – Hansei looks at personal failures rather than systemic or process issues. It can be gauged on a personal level based on employee performance in a project life cycle. Begin with classifying the problem and determine which area of focus you want to reflect on.

- Ask self-reflective questions – Self-reflective questions will help understand the reasons and assumptions behind weaknesses and committed mistakes. It helps comprehend failures by not blaming other people and being emotionally attached to them. Accept the accountability and admit undesirable outcomes to effectively plan on how to improve in the future.

- Plan the next actions – Review and analyze answers to self-reflection questions and commit yourself to rectification and improvement needs. Break down problems into smaller issues and create a detailed action plan on how it would improve and prevent the same mistakes.

The main goal of Hansei is to identify problems, develop rectification, and communicate lessons learned within the organization to help prevent the recurrence of multiple failures. This would help the organization maintain its profitability, save internal costs, and improve the overall employee and organizational performance.

Perform Hansei Anytime Anywhere

Identify issues and carry out actions with our digital platform.

Get Started for FreeWhat is the Ideology Behind the Hansei Concept?

Hansei is one of the thirteen pillars of the Toyota Production System. It was established to empower people to find better ways of performing their tasks and develop an organization that focuses on continuous improvement leaning towards standardization. It is a critical part of organizational learning along with Kaizen and sometimes is compared to “check” in the plan-do-check-act (PDCA) improvement cycle as it focuses on analyzing good or bad results to prevent any recurring issues or mistakes.

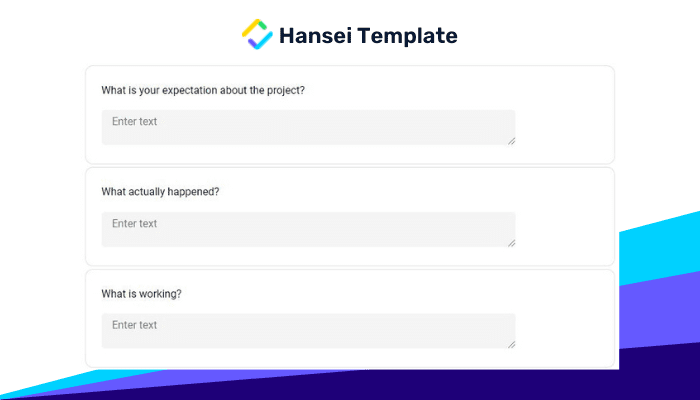

Performing Hansei or “self-reflection” is a practice of reviewing personal shortcomings to avoid recurring mistakes and implement continuous improvement. Identify mistakes and weaknesses by answering the following questions:

- What is your expectation about the project?

- What actually happened?

- What is working?

- What is not working?

- Did you get the planned results?

- What did you learn?

- What are your plans to avoid the same mistakes?

Taking Advantage of a Digital Hansei Template

Performing Hansei in lean manufacturing can be challenging since the scope seems overwhelming, but with SafetyCulture (formerly iAuditor), an inspection app that can be used through the web or mobile platforms, you can maximize technology and ensure collaboration and accountability within the organization. With SafetyCulture, you can:

- Create and customize templates

Use our ready-to-use Hansei template or check out our Public Library of free checklist templates. You also have an option to convert your existing PDF, Word Document, Excel, or PowerPoint files into SafetyCulture checklist for free up to 3 files. - Access, review, and share reports in real-time

Instantly share your Hansei report to any member of the organization, you have an option to send reports on the mobile app to specific people via email. All data is automatically stored in the cloud, which you can access anytime, anywhere. - Assign and complete actions

To achieve continuous improvement, you can simply assign and share corrective actions to any member of the organization to prevent committing the same mistakes.

Embrace Hansei to improve the quality of work and implement continuous improvement in your workplace. Set up the organization for operational excellence. Get started with SafetyCulture’s ready-to-use templates.