Published 19 Feb 2026

Article by

3 min read

What is a CCP Monitoring Form?

A CCP monitoring form is a document often used in food safety systems to track the current status of Critical Control Points (CCPs). These are key steps in the food preparation process where a control measure can be implemented to prevent or address a food safety hazard.

Why It’s Important

The Hazard Analysis Critical Control Points (HACCP) Principles are key steps established by the Food and Drug Administration (FDA) to help food safety systems assess hazards. A CCP monitoring form addresses the fourth principle, which requires regular reviews of critical control points to spot issues early.

Using a CCP monitoring template makes it easier to spot issues like high fridge temperatures or signs of cross-contamination. Keeping track of these issues helps prevent foodborne illnesses and bacterial growth throughout the food preparation process.

Information Included in a CCP Monitoring Form

A CCP monitoring form should consist of the following fields to facilitate easier completion by team members and enhance clarity during audit checks:

Date and time of check: Exactly when the check happened to help spot patterns over shifts (e.g., "Feb 16, 8 AM")

Person responsible: Name or signature of the staffer to promote accountability and assign a point person if something goes wrong

CCP description: What you're monitoring to pinpoint which unit or area should be diagnosed when issues arise (e.g., "fridge temp for raw chicken")

It must also include key measurements that provide hard data, comparing them against established safe limits to quickly identify bacterial risks. A few examples of these are the following:

Actual reading vs. critical limit: Indicates whether current values meet temperature requirements or require action.

Frequency: Notes how often (e.g., hourly, per batch, etc.) the check was performed to match HACCP schedules for full coverage.

Corrective actions: Logs fixes for reference in case the same issue reoccurs and shows proof that the issue has been addressed.

Proper Way to Fill Out a CCP Monitoring Form

Accurately completing a CCP monitoring checklist shows that your kitchen practices safe food handling, helping you pass audit checks smoothly. To ensure it’s done properly, your trained staff should follow these steps while using calibrated tools:

Enter the basics upfront: Fill in the date and time (e.g., "Feb 16, 8 AM"), name and signature of the person completing the form, and the description of the CCP (e.g., “fridge for raw chicken”).

Perform the check: Measure immediately, specifying the tools used and the frequency of the check.

Record numbers: Write down the actual reading (e.g., 3°C) next to the limit (<5°C). Mark "OK" or "NO" to indicate if the actual value meets requirements.

Log corrective actions: Record what was done to resolve the issue (e.g., “Adjusted temp, rechecked at 2°C”).

Verify and sign off: Have the supervisor review the form to ensure that no fields are left blank. Make sure to store completed forms digitally for easy audits.

Identify patterns: Check for trends such as recurring high temperatures to diagnose possible unit issues or retraining needs.

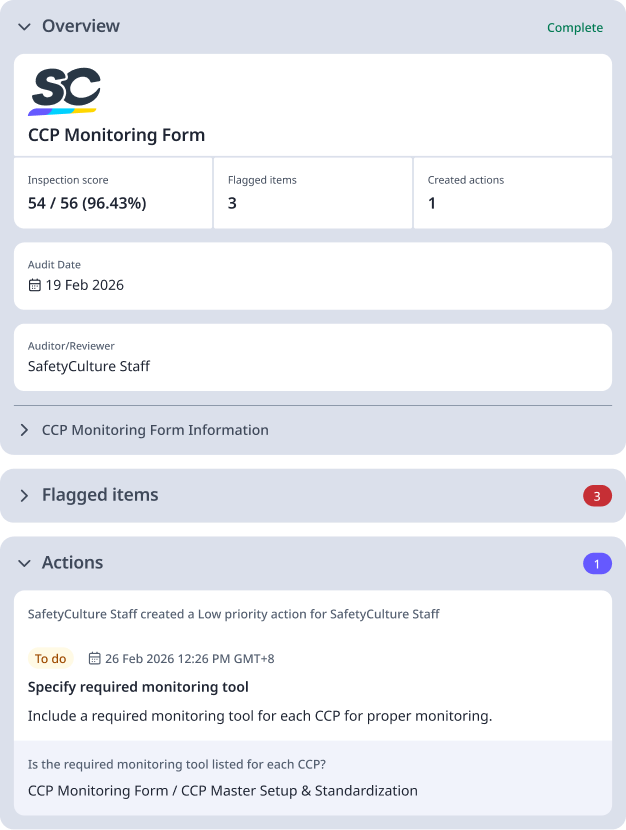

Sample CCP Monitoring Report

Below is a sample of what a CCP monitoring report looks like: