Published 19 Dec 2025

Article by

3 min read

What is a Structural Steel Inspection Checklist?

A clear, practical structural steel inspection checklist is what keeps steel structures like buildings and bridges consistent, safe, and compliant. It provides a simple system that makes sure every nut, bolt and material meets the right structural steel standards from pre-installation through to erection. The right structural steel inspection checklist can help teams get ahead of the risks that come with heavy steel work.

Importance

A structural inspection checklist is needed for any construction to get the whole team aligned and on the same page. There are a few important reasons why teams rely on a detailed structural steel fabrication and erection inspection checklist, such as the following:

Team coordination: A structural steel inspection checklist ensures Heating, Ventilation, and Air Conditioning (HVAC) crews, contractors and onsite teams stick to the same plan so one missed step doesn’t add extra downtime or costs.

Full documentation: Every stage can easily be tracked and recorded with a checklist, giving you a clear view of progress and where time and budget are being spent.

Quality assurance: Welds, bolts, beams, and other equipment are checked for consistency during installation and after erection with help from a checklist to make sure everything meets the right standard.

With the right structural steel inspection checklist for your needs, you can be assured of a safe, reliable build that holds up over time.

What to Include in a Structural Steel Inspection Checklist

There are many structural steel requirements that need to be checked during a build. Here are the most common areas teams inspect:

Pre-installation activities: Make sure everything is labeled, nothing is missing, baseplates are set in the right place, and all bolt testing and metalworking are complete.

Structural steel erection: Check that all columns are plumb in every direction and within tolerance, welding meets the set Welding Procedure Specification (WPS) and bracing is bolted correctly, along with other required checks.

Platforms, ladders, and access systems: Ensure that grating, floor openings, fixed ladders, cages and stairs with handrails are installed to Occupational Safety and Health Administration (OSHA) requirements and project specs.

Coatings, grouting, and fireproofing: Inspect that grouting at baseplates is cleanly finished, coating touch-ups are complete, and any fireproofing repairs are done, along with other required checks.

Documentation and close-Out: Record all details from erection, bolting, Nondestructive Evaluation (NDE) reports, welding logs and final inspections to make sure everything is complete and traceable.

How to Use a Structural Steel Inspection Checklist

Having the right checklist ready before every shift helps your team spot issues early and keep the job moving. It’s no different from laying the foundation of a structure. If the materials, standards and equipment aren’t right from the start, everything that follows is harder than it needs to be.

Here’s a simple way to use a structural steel inspection checklist:

Schedule prefabrication meetings to review building plans, from the material used to how long it would take to finish.

Walk the construction site with your checklist on an accessible device to easily spot for safety hazards, incorrect storage, or anything that could slow down construction time.

Verify materials, tools, and equipment readiness before starting construction to ensure everything is in proper working condition.

Conduct phased inspections to review welding, bolting, and equipment work before, during, and after construction.

Record and document photos once the structure is finished to provide traceable progress for supervisors and Quality Assurance (QA) teams.

Sample Report

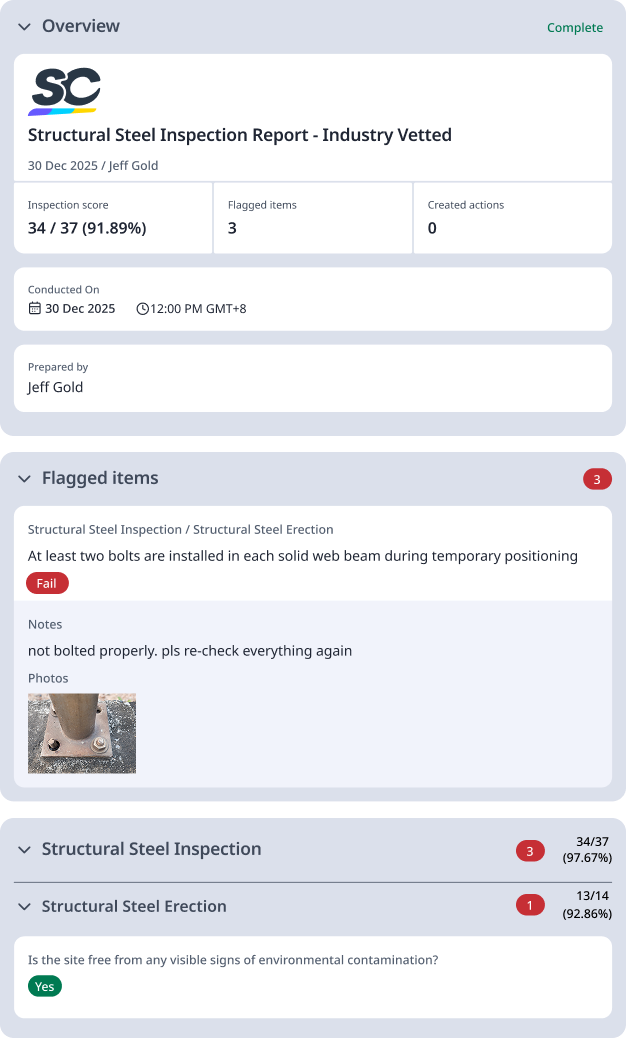

Here is an example of a structural steel inspection checklist in use for reference:

Structural Steel Inspection PDF Sample